Automotive Belts

Home - Automotive Belts

Automotive Belts

The engine of a vehicle has several various components that perform different functions. However, none of these parts would work had there been no Automotive Belt. There are different types of Automotive Belts, and their job is to keep the engine running by transferring power to various parts.

Sri Rama Marketing Associates distributes an extensive range of Automotive Belts and covers the whole range of vehicle engines. SRMA-Force® Automotive Belts are available for two-wheelers, cars, vans, trucks, buses, heavy and light-duty vehicles and manufactures Belt for the aero engines as well.

The Product Range of Automotive Belt includes-

SRMA-Force® Moulded, Raw Edge Cogged, Automotive Belts

They originate from the crankshaft, run through various components including the alternator, power steering pump, AC compressor, water pump and supply them with power to function. These are mostly seen in older cars.

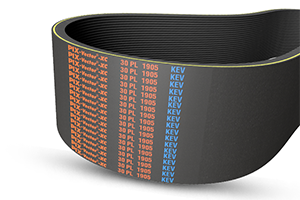

SRMA-Force® Ribbed /Poly-V Automotive Belts

A prolonged serpentine Automotive Belt that runs through all engine components and powers them. A single Belt supplies power to almost all engine accessories and multiple components.

SRMA-Force® Synchronous/Timing Automotive Belt

Also known as a camshaft drive belt, the job of a timing belt is to help crankshaft turning the camshaft. The Timing Belt opens and closes engine valves with the pistons in a synchronized fashion.

FAQ - Automotive Belts

Automotive Belts are essential components in vehicles that transmit power from the engine to various accessories or systems, enabling their operation.

Common types include the Serpentine Belt, Timing Belt, V-belt, Multi Ribbed Belt (Poly-V Belt), and specialty Belts, each serving different functions within the vehicle.

These Belts power critical components such as the alternator, water pump, power steering pump, air conditioning compressor, and sometimes the cooling fan or camshaft.

They are typically made from durable materials like rubber compounds reinforced with synthetic materials such as polyester, aramid fibers, or metal cords for strength and longevity.

Signs include visible wear, cracking, fraying, loss of tension, squealing noises, or failure of accessories powered by the belt.

Replacing certain Belts might be a DIY task for some individuals with proper knowledge, but for complex Belts like the Timing Belt or serpentine belt, professional assistance is often recommended.

Regular visual inspection for wear, proper tension adjustment, alignment checks, and adhering to manufacturer-recommended maintenance schedules are vital for longevity and performance.

Extreme temperatures, both hot and cold, can impact belt performance, so maintaining and replacing Belts according to schedule is crucial in harsh conditions.

If a belt breaks while the engine is running, it can lead to the failure of accessories it powers, potentially causing engine overheating, loss of power steering, or electrical issues.